Chemicals management activities

The Kao Group handles a wide range of chemicals in manufacturing of its consumer and industrial products. Kao developed its own “Comprehensive Management System for Chemical Substances” and started implementing the system since 2001. Under the system, Kao practices appropriate management of chemicals including safety assurance, quality assurance of raw materials and products, and compliance with the laws and regulations in various countries.

Kao has been and remains committed to enhancing and promoting its chemicals management activities. The “SAICM*1Promotion Committee” launched in 2012 as a group-wide organization that leads Kao’s chemicals management activities, and “Responsible Chemicals Management Promotion Policy” set down in 2013 based on the internationally harmonized chemicals management initiative. Subsequently, SAICM was succeeded by the GFC (Global Framework on Chemicals) in 2023, and the SAICM Promotion Committee was renamed the GFC Promotion Committee. From 2025, we further strengthen and promote chemical substance management activities in line with "the Kao Chemical Stewardship Policy", principles that guide us in the use and management of safer and more sustainable chemicals.

In recent years, the number of various regulations on chemicals adopted globally has been growing rapidly. Such regulations include regulations on chemicals registration, regulations on SDS and product labeling that are compliant to GHS*2, and regulations on substances contained in the final products. In response to such global regulations, Kao Chemical Business Unit carries out the following chemicals management activities for the purpose of fulfilling the company’s responsibility in supplying products.

Chemical substance registration

Domestically, Kao observes Japanese laws and regulations on chemicals such as CSCL*3. Globally, Kao observes REACH*4 (European regulations on chemical products) and other laws and regulations adopted at manufacturing and export destination countries.

Risk assessment of chemicals

Risk assessment results obtained through the chemical substances registration in various countries and activities of the GFC Promotion Committee are put together into the form of GPS Safety Summary and disclose them on product information section of Kao Chemicals website as they become available.

On promoting risk assessment of chemicals in accordance with GFC, we established our own risk assessment policy.

Based on the guidance issued by the International Council of Chemical Associations (ICCA), Kao has been diligently working on risk assessment of chemicals.

Safety summary for chemicals are disclosed that underwent risk assessment by Kao’s GFC activities.

Regarding the chemicals registered in REACH (EU’s chemical substance registration system) etc., safety information has been disclosed as GPS Safety Summary of Kao chemical products.

Management of chemicals contained in products

Kao strives for the management of chemicals contained in products by establishing an organization consisting of personnel from the research and development, procurement, production, Quality Assurance and sales departments. As one of the founders of the Joint Article Management Promotion-consortium (JAMP), Kao promotes the providing of information to its customers using “chemSHERPA”*5 (a common form for listing chemicals included in products) by JAMP.

GHS-compliant SDS and product labeling

Various countries started to implement GHS correspondence after Japan commenced implementation in 2006 (revised Industrial Safety and Health Law). For products of Kao Chemicals, we promote issuance of Safety Data Sheet (SDS) in compliance with Japanese and overseas laws and regulations and affixing of product labels.

*1 SAICM: Strategic Approach to International Chemicals Management

*2 GHS: Globally Harmonized System of Classification and Labelling of Chemicals

*3 CSCL: Chemical Substances Control Law. The full name is “Act on the Evaluation of Chemical Substances and Regulation of Their Manufacture, etc.”

*4 REACH: Registration, Evaluation, Authorization and Restriction of Chemicals in EU.

*5 chemSHERPA: Information transmission sheet for specific chemical substances

Comprehensive Management System for Chemical Substances

In order to ensure the safety, quality, regulatory compliance, and traceability of consumer and industrial products, the Kao Group developed and adopted its own “Comprehensive Management System for Chemical Substances” where each material and product is assigned with group-common codes called “Master Index (MI)”. Features of the Kao Comprehensive Management System for Chemical Substances are as follows.

-

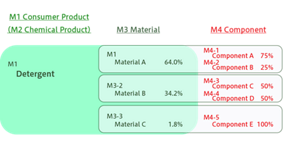

Master Index (MI), the key code of this system, has a stratified structure consisting of M1-M4 (see the diagram below) and allows for instant tracing of Kao products to the components (substances) as well as identification of products tracing back from an component. This system enables ensuring the traceability of products and thus swift response to new or revised regulations, quality troubles, etc., by instantly identifying the area of influence.

Hierarchic structure of Master Index

-

Various kinds of information (such as product and raw material composition, Safety Data Sheet, laws and regulations in various countries, safety data, and relevant documents) are integrally managed under this system and shared among relevant departments. It also contributes to drastically reducing the time required from designing to marketing of our products.

-

Substance Volume Tracking (SVT) of chemicals that is compliant with CSCL or REACH is realized by tracking products to the substances and by linking them with the production, shipping and import/export information stored on our core system and information on use at customers. SVT allows for gathering of accurate information on quantity used, quantity manufactured, and quantity released for the substance regulated by the Act on Pollutant Release and Transfer Register (so-called “PRTR Act”) or volatile organic compounds (VOCs).

This system is also effectively used for investigating their compliance to laws and regulations in countries, contained substances that may be subject to special requirements or regulations, etc, on the products sold to customers, in response to inquiries made by the customers.

Risk assessment policy

(1) Scientific risk assessment methods are adopted

Referencing the methods specified in domestic and international chemicals regulations (e.g., CSCL, REACH) or SCCS*, risk assessment is carried out using the method based on scientific grounds with viewing the latest international trends in risk assessment.

*SCCS: European Scientific Committee on Consumer Safety

(2) Existing safety information is fully utilized

There is a wide range of safety information used for risk assessment in addition to the Kao’s database, such as information from internationally credible risk assessment documents, academic papers, and any database held by public institutions, and such information is fully utilized in risk assessment conducted by Kao. If safety data required for risk assessment is insufficient, we obtain further necessary safety data. Safety information obtained by new methods such as in silicoassessment (e.g., quantitative structure-activity relationship, categorical approach) are proactively used in risk assessment within the range where the reliability is guaranteed.

(3) Reliability of information used is ensured

The reliability of safety information used for risk assessment is comprehensively evaluated based on the compliance with the test guidelines accredited domestically or overseas (e.g., OECD Guidelines for the Testing of Chemicals*) , the test conditions adopted, physicochemical properties of the substance, reproducibility of the test results, and dose-response relationship. Kao adopts scientifically proven information only.

*http://www.oecd.org/chemicalsafety/testing/oecdguidelinesforthetestingofchemicals.htm

(4) Risk assessment of categorized chemical is carried out

Risk assessment of multiple chemicals with a similar toxicity profile (e.g., a certain regularity identified in their physicochemical properties and toxicological properties) is carried out by putting them into one category. This method of risk assessment avoids acquisition and distribution of redundant data and therefore leads to more efficient and effective risk assessment.

(5) Risk assessment is processed in stages

Risk assessment is processed in stages depending on the quality and quantity of information available. If risk assessment using existing safety information identifies the risk acceptable, additional assessment by obtaining new data will not be carried out in principle.

Risk assessment procedure

“Risk of chemicals” is the possibility of undesirable effects on human health or the environment by chemicals . Risk of a chemicals is assessed by the hazard of the chemicals and the exposure to the chemicals.

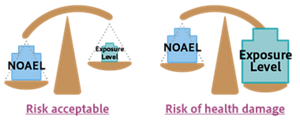

Hazard assessment of chemicals is to thoroughly investigate what kind of adverse effects emerges at what dose, and usually it refers to determining the maximum acceptable amount that does not cause an adverse effect on human health or organisms in the environment (no observed adverse effect level (NOAEL) or no observed effect concentration (NOEC)). Exposure assessment is to assess the exposure or amount of intake of chemicals for humans or organisms in the environment.

Therefore, risk assessment of chemicals, for instance in the case of adverse effect on general organisms, refers to comparison of NOAEL and the exposure, and the risk of chemicals varies depending on the exposure if the NOAEL was the same. If risk assessment finds a substance having a possibility to cause adverse effect, stricter and more detailed management appropriate to the risk is applied for the chemical.

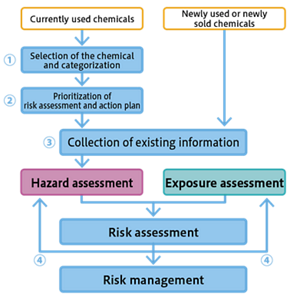

At Kao, appropriate risk assessment and management are carried out for newly used or newly sold chemicals prior to marketing, depending on their purpose of use. Meanwhile, risk reassessment is carried out for currently used chemicals using the latest safety information and assessment methods from the viewpoint of GFC, in addition to risk assessment carried out in the past prior to marketing, aiming at realization of more appropriate chemicals management. Risk assessment of chemicals is carried out by the following procedures in accordance with our risk assessment policy.

-

Risk assessment of multiple chemicals with a similar toxicity profile (e.g., a certain regularity can be identified in their physicochemical properties and toxicological properties) is carried out by putting them into one category.

-

Prioritization of risk assessment is reviewed regularly taking into account the change in the production amount or use amount (i.e. exposure for humans and the environment) and based on the regulations in the world, social concern over certain chemicals, etc.

-

Hazard information of chemicals is compiled by utilizing data possessed by Kao as well as information in internationally credible risk assessment documents, academic papers, and database held by public institutions.

-

If risk assessment using existing information indicates a chemical having a possibility to cause adverse effect on human health or the environment, risk assessment will proceed to the next step, namely, a more detailed risk assessment by acquisition of new data.

Kao’s Safety Summary of chemicals for priority risk assessment

In 2013, the Kao Group selected chemicals groups (categories) for priority risk assessment, and established a medium-term risk assessment plan that runs until 2020.

In this assessment plan, chemicals for priority risk assessment are selected taking into account various factors including the manufacture quantity, use and amount of use in the Kao Group, exposure level for humans and the environment, and the importance in Kao’s business activities. Kao will strive to carry out thorough risk assessment of chemicals under this risk assessment plan, and disclose safety summary describing the assessment results for experts and enterprises that handle chemicals.

Kao’s Safety Summary downloads

Polyoxyalkylene alkyl ether

GPS safety summary of Kao Chemical products

Regarding the chemicals registered in REACH (EU’s chemical substance registration system) etc., safety information has been disclosed as GPS Safety Summary of Kao chemical products.