Global Chemicals

Kao Thailand

ภาษาไทย| English

- Home

- Business Fields

- Casting

Business fields

Casting

Business fields

Casting

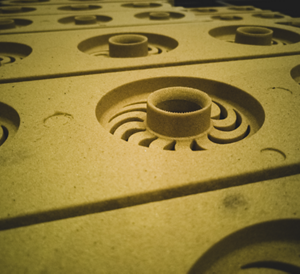

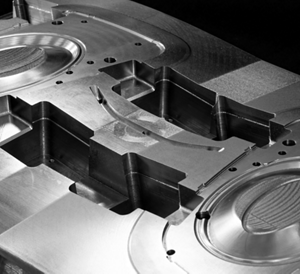

In the foundry industry, the decision to use chemical binder systems in a foundry operation for molds and cores is based on the evaluation of many factors such as production rate, capital outlay, operating cost, quality level, environmental impact, skill of labor, sand available and so on. Kao is one of the world leaders of foundry supplier.

Furan

no-bake system

Furan binders contained resin and catalyst which the two chemicals will be use either for sand mixing to harden the sand mold. Suitable for FC and FCD casting which requiring best sand reclaimable around 90%.

KAO LIGHTNER series

Resin (Strength control)

High performance type

KAO LIGHTNER EF-55AT

KAO LIGHTNER EF-51AT

Conventional type

SF-301B

SF-32B

Catalyst (Curing speed control)

High performance type

KAO LIGHTNER EC-3T

KAO LIGHTNER EC-10T

Conventional type

KAO LIGHTNER TK-3T

KAO LIGHTNER C-14T

KAO LIGHTNER C-17T

KAO LIGHTNER C-19T

KAO LIGHTNER C-21T

Low Sulfur type

KAO LIGHTNER NC-03T

KAO LIGHTNER NC-25T

Low corrosion type

KAO LIGHTNER TK-3TL

KAO LIGHTNER C-14TL

Alkaline phenol

no-bake system

Alkaline phenol binders contained resin and hardener components which the two chemicals will be use either for sand mixing to harden the sand mold. Suitable for FC, FCD, and steel casting which recommended of sand reclaimable around 70%.

KAO STEP series

Resin (Strength control)

KAO STEP SH-8010TA

KAO STEP S-654T

KAO STEP C-810T(resin foe CO2 curing process)

Hardener(Curing speed control)

Conventional type

KAO STEP QX-125F

KAO STEP QX-150

Low smell type

KAO STEP QX-125R

Coating agents

Application basically applied on sand mold and core to prevent heat from molten metal during pouring process

FURANCLEAN series

Alcohol based coating

FURANCLEAN OSK-59TN

FURANCLEAN OSK-592GV

FURANCLEAN OSK-592BS

FURANCLEAN OSK-593

FURANCLEAN OSK-59S

Water based coating

FURANCLEAN PC-200T

Releasing agents

Applied on wood pattern for accommodate during stripping process of sand mold

KAO COAT SILVER

Casting materials

A pulp runner tube using in iron casting supplied in various size and shape

EG RUNNER

Straight tube

Elbow tube

Cone tube

- Home

- Business Fields

- Casting