- Home

- Digital printing materials

- Water-based, pigment inkjet ink LUNAJET

- What is LUNAJET?

What is LUNAJET®?

LUNAJET® is a water-based pigment inkjet ink that was developed using Kao's proprietary pigment nano-dispersion technology, interface control technology, polymer design technology and polymer coating technology.

Pigment nano-dispersion technology

Background behind the development of LUNAJET®

Pigments used in inkjet inks are extremely fine, and as a result, the pigment particles agglomerate with strong force against each other. In order to stabilize pigments in ink, ink manufacturers are developing ink formulations in various methods.

Kao has focused on the capsule type, which is self-adsorption, and has developed pigment dispersions.

Kao’s water-based pigment ink is based on five technologies.

In a hydrophilic environment, LUNAJET® remains highly stable due to the charge repulsive group, and in a hydrophobic environment, the charge repulsive group does not work effectively, helping it to maintain high stability due to the steric repulsive group.

In a hydrophilic environment, LUNAJET® remains highly stable due to the charge repulsive group, and in a hydrophobic environment, the charge repulsive group does not work effectively, helping it to maintain high stability due to the steric repulsive group.In addition, the surface of the pigment is coated with a polymer, and by making full use of these, a dispersive stable group, charge repulsive group and a steric repulsive group built into the polymer, create an encapsulated pigment dispersion facing outward.

Kao originally developed a polymer dispersion containing charge repulsive groups and steric repulsive groups, and by coating the pigment surface with the polymer dispersion, developed an encapsulated pigment dispersion that disperses the pigment at the nano-level and has high stability under hydrophilic and hydrophobic environments. (the size of the pigment dispersion is 50 to 120 nanometers.)

This technology suppresses pigment clumping, enabling the stable dispersion of pigments in ink.

Stable ink jetting can also be achieved even with long printing times, and stable image quality can be obtained because the pigments are uniformly dispersed on the media.

As a result, we succeeded in developing a water-based pigment inkjet ink that reduces the environmental load of soft package films, which had previously been difficult to print on using water-based inks.

Features of LUNAJET®

The ink designed by Kao can be printed on substrates with different ink absorbability and ink contact angles without primer.

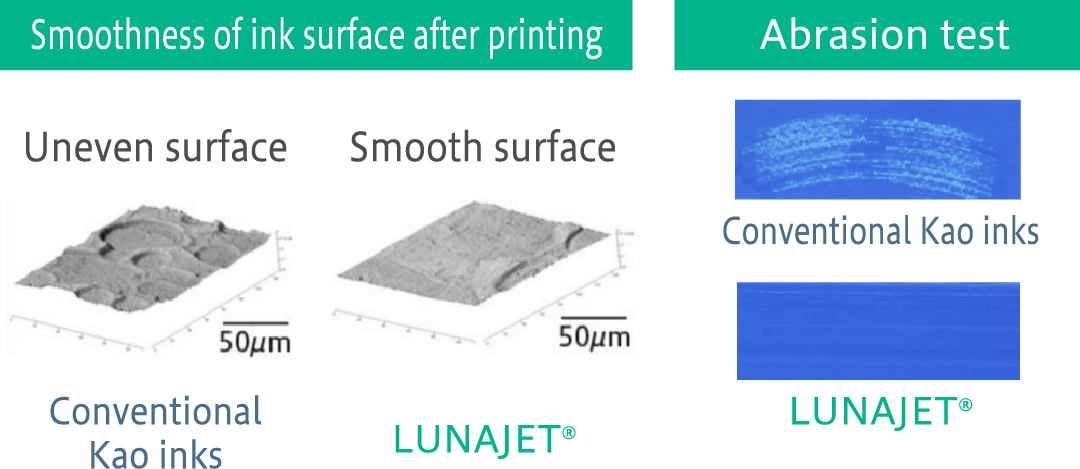

Because the smooth surface of the ink after printing, it is possible to achieve highly abrasion resistance.

Because LUNAJET® emits almost no volatile organic compounds (VOC), it reduces VOC emissions in printing processes and improves the printing environment.

By applying our unique pigment nano-dispersion technology, high-quality printing is achieved, and because no odor remains after printing, it can also be used for the printing of food packaging.

Please use the form below to request samples and further information about LUNAJET®.

- Home

- Digital printing materials

- Water-based, pigment inkjet ink LUNAJET

- What is LUNAJET?