CRESCENTIS™, a saccharification enzyme that enables the utilization of non-edible biomass

Convert what you have thrown away into value

Kao has conducted research and development into developing and manufacturing its distinctive enzymes and used those enzymes in its own products. Given the increasing use of biomass and the growing need for high-performance saccharification enzymes, Kao plans to produce saccharification enzymes necessary for bioethanol fuel production to meet the needs of customers in Japan and abroad, in the expectation that this will help reduce industry CO2 emissions and contribute to creating a sustainable future.

Produce ethanol using agricultural residues

Ethanol manufacturer

Create a new ethanol business

Paper / food Manufacturer

CRESCENTIS™, Kao’s unique saccharification enzyme

Kao has been researching enzyme for detergents for many years and has unique saccharification enzyme technology that leverages the knowledge it has cultivated. Using this technology, we have developed a saccharification enzyme suitable for non-edible biomass, which is generally considered difficult to decompose, and have made it possible to convert it into sugar with high efficiency. The resulting non-edible sugar is fermented to become non-edible ethanol, which is then turned into bio plastics and aviation fuel.

Ethanol derived from non-edible biomass and its expansion

We will propose the supply method of saccharification enzyme tailored to customer's need.

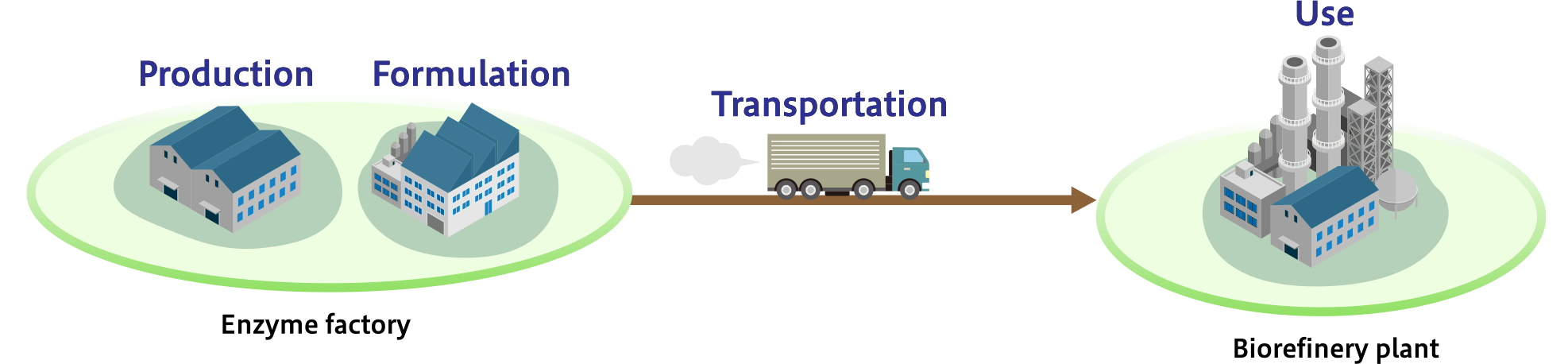

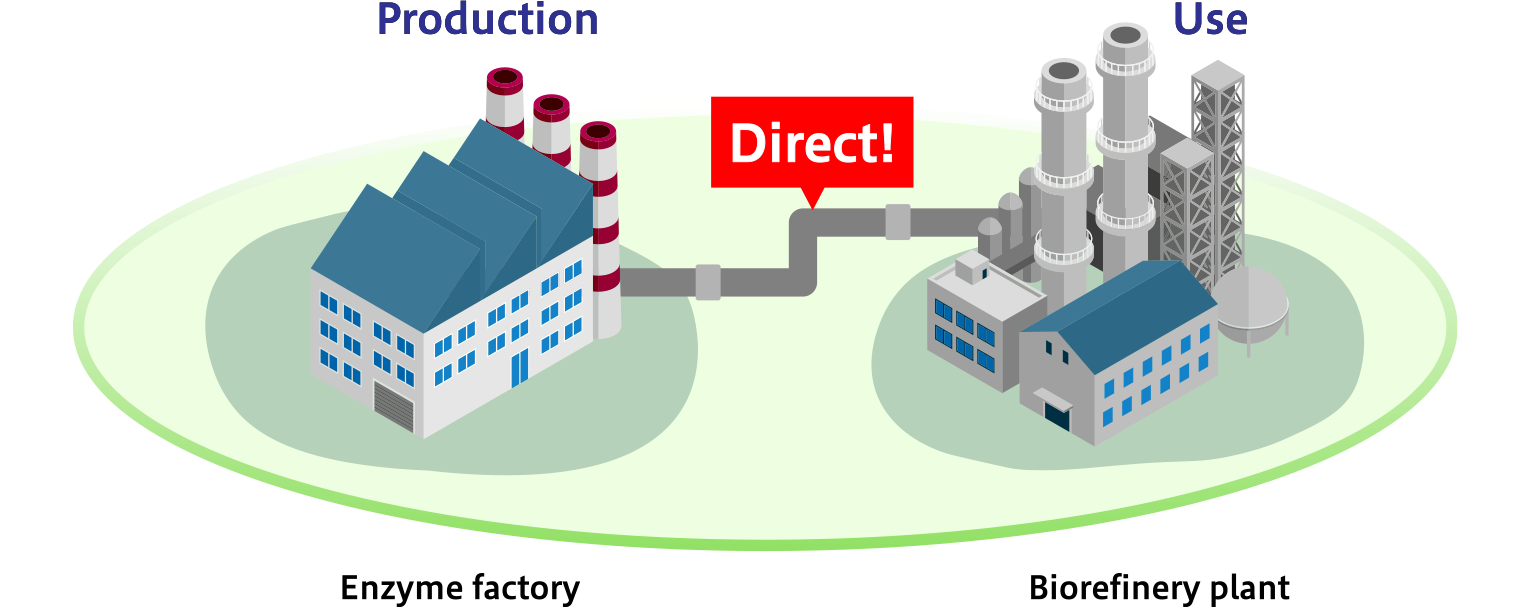

The saccharification enzyme required for the use of non-edible biomass are generally transported by truck or ship to biorefinery factory that process the biomass and produce chemical products ("Off-site supply"). Kao proposes "On-site supply" system that produces enzyme using Kao's enzyme-producing strain on the same premises as the biorefinery factory and supplies them directly. On-site supply does not require formulation or transportation, so it can be expected to reduce costs and CO2 emissions. Furthermore, there are many benefits to commercialization, such as avoiding unexpected risks in the supply chain.

Advantages

- Cost reduction

- CO2 emission reduction

- Enhancing resilience

Creation of new business

Decarbonization

Cost reduction

If you have any questions or require additional information about CRESCENTIS™, please use the form below.

Bio-Chemical Products

Bioaromatic Compound Production Technology

Bio Gallic Acid GA-100 BIO