- Home

- Case studies

- MEICHU INC.

MEICHU INC.

Improved productivity and quality by reducing burn-on

MEICHU INC.

Improvement

Improvement

MEICHU INC. (Toyokawa, Aichi) is a foundry established in 1938 whose main product is automotive press molds.We have a wide range of business partners, from major domestic manufacturers to overseas manufacturers, and our plant with a monthly production of 1,250 ton is one of the largest in Japan. Pictured are Executive vice-president, Sukeyuki Furuta (middle), Director/Plant Manager, Shigehiko Oshima (right), and Engineering Department Assistant Manager, Toshiaki Fukui (left).

Introduction of full-mold casting and the importance of core wash and mold paints

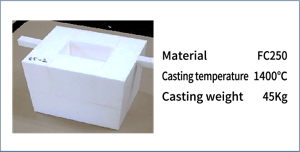

MEICHU began production of automotive press molds in 1950 and introduced the current full-mold casting method in 1967. Full-mold casting is a casting process where a mold made from polystyrene foam is covered in sand. High temperature molten metal (molten steel) is then poured into the mold which vaporizes the foam leaving only the casting. In this process, the role of the core wash and mold paint is to prevent a reaction between the molten metal and sand (hardening) and to release the gas resulting from thermal decomposition of the foam model, and the performance of the core wash and mold paint directly relates to the quality of the casting.

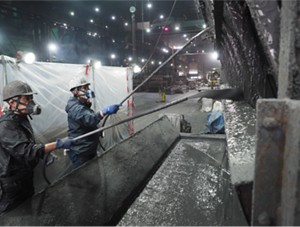

Casting scenery of full mold casting method

Study of core wash and mold paint for full-mold casting

MEICHU was initially using a core wash and mold paint from another supplier, but it was difficult to obtain satisfactory casting quality, so we were going through a process of trial and error. It was through this process that we came across a Kao-Quaker product. "Kao Quaker's product was the most highly rated after testing coating agents from a variety of manufacturers," recalls Director/Plant Manager, Oshima.

Coating the model with core wash and mold paint

Working to improve two conflicting issues

Casting using the full-mold casting process poses two major issues: "burn-on" and "residue" (residue resulting from the burnt gas of the mold remaining on the surface of the casting). These two issues proved to be extremely challenging, because improvement of one would worsen the other. MEICHU and Kao-Quaker engaged in talks with the aim of rectifying these two conflicting issues and after repeated testing, began work on the development of a new core wash and mold paint together. This resulted in FURNCLEAN PC-290.

Burn-on

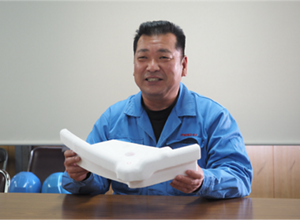

Mr. Fukui, Second Director of The Technical Department, realized the effect of the core wash and mold paint

Improved productivity and quality

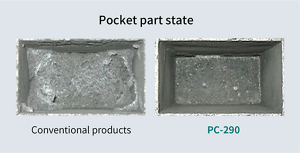

Since we started using FURNCLEAN PC-290, we have significantly improved burn-on and residue compared to previous products. "Compared to before, the number of times we have to change tools to remove burn-on has been reduced, so we can see the effect," replies Engineering Department Assistant Manager, Fukui with a smile. In addition, the reduction in work time due to the reduction of burn-on has led to an improvement in productivity, and the reduction of residue has improved casting quality.

Mr. Furuta, Managing Director, talked about the future of casting with a model in hand

A new future with quality improvements

With improvements in the area of automotive design and performance, foundries are now, more than ever, required to deliver precision products. Kao-Quaker products have become an essential part of our daily efforts to meet these demands. Senior Managing Director, Furuta comments on how the company image, one that delivers quality products as a result of the reduction of burn-on and residue, has brought them more work. Kao-Quaker products have not only improved productivity, but has also helped to attract new customers.

Product information

FURNCLEAN PC -290 (water-based core wash and mold paint for full-mold casting)

Reduced finishing time and improved productivity due to less burn-on and residue

-

Superior burn-on resistance due to high fire resistance and hot strength.

-

The addition of a special filler helps to maintain high permeability, improving defects caused by residue.

Improved casting quality as a result of enhanced coating properties

-

Because it helps to create a uniform film during application, it has good fluidity and can be applied with less paint residue, drips and lumps.

Technical information

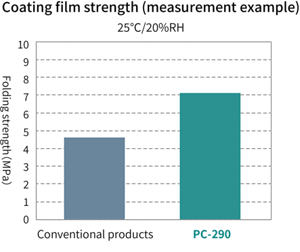

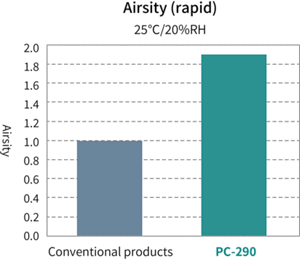

FURNCLEAN PC-290 has achieved improvements in both film strength and permeability.

FURNCLEAN PC-290 performed better than conventional products in burn-on resistance tests, showing less burn-on.

Burn-on resistance test

- Home

- Case studies

- MEICHU INC.