- Home

- Product information

- Alkaline phenol binders for casting sand KAO STEP

Alkaline phenol binders for casting sand KAO STEP

Alkaline phenol binders harden the mold as a result of a chemical reaction between a highly alkaline phenol resin and organic ester.As a process capable of producing high quality castings, this process is the second most popular in labor intensive, high-mix, low-volume production, following furan self-hardening binders.

Features of KAO STEP

-

Because the binder does not contain sulfur (S), there are no sulfur-derived casting defects and odors during pouring can be reduced.

-

Due to the high collapsibility of the mold (mold does not show deformation as a result of the hardening of the casting), it is possible to reduce thermal cracking and veining.

-

Past issues, such as the yield rate of recycled sand and mold strength can be drastically improved.

-

We also offer products with a range of features, such as improved curing speed, longer pot life, easier mold release after pouring, and reduced odor.

-

In place of organic esters, we also offer gas-cured alkaline phenol resin that can be cured instantly with carbon dioxide.

-

We are working proactively to reduce our green house gas emissions, which contribute to global warming. 100% of the power used to manufacture our alkaline phenol resins is renewable energy.

Pick out! Solvable Products

Improved mold productivity Alkaline phenol self-hardening resin

KAO STEP SH-8300

KAO STEP SH-8300 is an alkaline phenol self-hardening resin that combines the features of "fast hardening" and "extended bench life".

Product features

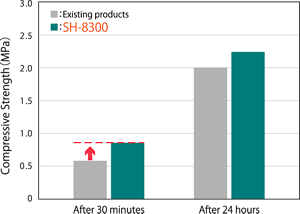

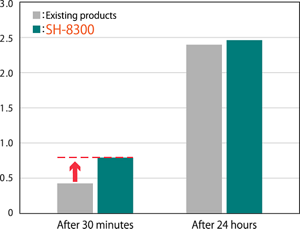

(1) Fast hardening

-

Mold stripping time can be shortened.

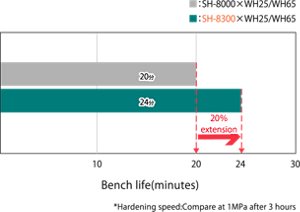

(2) Extension of bench life

-

Moulding workability is improved

Fast hardening

When compared with the same hardener, the hardening speed can be improved while maintaining the bench life

<5℃/55%RH>

<25℃/55%RH>

- Types of Sand: Reclaimed silica sand

Dossage of resin: 1.3% based on sand

Hardener type: WH-10(5℃), WH-25(25℃)

Dossage of hardener: 20% based on resin

Extended bench life

If the stripping time is constant at the same hardening speed, the bench life can be extended.

< Comparison of bench life >

- Evaluation conditions: 25°C/55% RH, Reclaimed silica sand

Dossage of resin: 1.3% versus sand

Dossage of hardener: 20% versus resin

Representative characteristic values

It can be handled in the same way as a standard product.

| Principal component | appearance | viscosity (25°C, mPa・s) |

specific gravity (25℃/4℃) |

pH (5% aqueous solution) |

Japanese Fire Service Act |

|---|---|---|---|---|---|

| Alkaline phenolic resin | Yellow~Reddish-brown liquid |

45 | 1.20 | 12.9 | Not applicable |

Packaging: Lorry, container (1,100kg), drum (230kg)

- Home

- Product information

- Alkaline phenol binders for casting sand KAO STEP