- Home

- Product information

- Core wash and mold paint FURANCLEAN

Core wash and mold paint FURANCLEAN

FURANCLEAN is a core wash and mold paint for high-quality casting and easy application.Kao-Quaker offers a range of unique products for a variety of applications, from aluminum castings to thick cast iron and cast steel castings.

Features of FURANCLEAN

- Superior in preventing collapse of spheroidal graphite particles in ductile cast iron castings unique to furan resin molds.

- We can propose products suitable for all applications, such as spraying, dipping and brushing.

- Superior burn-on resistance and prevention of veining helps to reduce finishing processes.

-

We can propose a range of quick-drying, water-based core washes and mold paints.

- Water-based core wash and mold paints for full-mold casting demonstrate a high resistance to burn-on and reduces residue defects in foam molds.

Pick out! Solvable Products

Quick-drying water-based coating agent FURANCLEAN DF-900

FURANCLEAN DF-900 is a water-based coating agent with excellent performance on "quick drying" and "burn-on resistance".

Product features

(1) Quick drying

-

Excellent in quick drying, can shorten the drying time and simplify the drying equipment.

(2) Burn-on resistance

-

It has excellent burn-on resistance and can reduce the removal work of the burn-on part.

-

It has the same burn-on resistance as general alcoholic coating agents.

Drying speed evaluation example (1)

Because it can be applied with a low moisture content, it dries faster than general water-based coating agent products with the same penetration depth.In addition, it can be dried even with simple equipment such as panel heaters.

< Comparison of moisture content during drying of coating agent (using infrared panel heater) >

- Drying conditions: Drying with panel heater

Heater size: 0.4 × 0.6 m²

Heater Output: 2kw

Irradiation distance: 0.1 m

Application area: 0.23 × 0.23 m²

Application method: flow coating

Coating concentration: Constant coating film thickness (in wet)

Maximum penetration depth: about 3mm

Drying speed evaluation example (2)

It is superior in quick-drying properties compared to existing water-based coating agents.

Representative characteristic values

| Principal component | appearance | Diluted solvent | Recommended concentration for use | Usage |

|---|---|---|---|---|

| Silica, graphite | Reddish brown Pasty |

water | flow coating: 50~56 Bé Brush coating: 54~58 Bé (Example at AFS-GFN=39 recycled sand) |

Ordinary cast iron Ductile Iron |

Packaging: Plastic bag (20kg)

FURANCLEAN OSK-7507NE

The FURANCLEAN OSK-7507NE reduces the three loads of "management", "work" and "cost".

Product features

(1) Japanese organic and specialization rules:

Not applicable

-

Since it does not fall under the japanese organic rule or the specialization rule, it can reduce the burden on compliance with laws and regulations.

(2) Reduction of coating film correction work

-

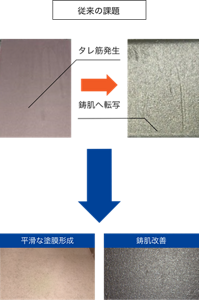

Since a uniform coating film is formed at the time of flow coating application, streaks after sagging is reduced and the load such as correction work is reduced.

(3) Reduction of usage

-

Low penetration characteristics can be expected to reduce the amount used.

-

Contributes to cost reduction by reducing the amount of expensive ethanol solvent used.

Merits of not falling under various laws and regulations

By utilizing OSK-7507NE, the following laws and regulations are not required*.

* Compliance with the japanese Fire Service Act is necessary

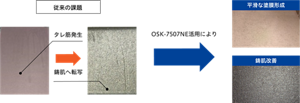

Improvement of casting surface by reducing streaks after sagging

Reduction effect of usage

< Evaluation of usage under the same conditions >

- How to paint

Recycled silica sand (AFS-GFN: approx. 49) used

After adjusting to each coating agent 24Bé

flow coating application to a sand plate (made by furan self-hardning process) with an inclination of 60 degrees

Representative characteristic values

| Principal component | appearance | Diluted solvent | Recommended concentration for use | use | Japanese Fire Service Act |

|---|---|---|---|---|---|

| Silica, graphite | Reddish brown Pasty |

ethanol | At the time of flow coating: 26~30Bé When brushing: 40~46Bé (AFS-GFN: Example with 42 recycled sand) |

Ordinary cast iron Ductile Iron |

Class 2 flammable solids Flammable solids (Specified quantity: 1000kg) |

Packaging: Can (20kg)

- Home

- Product information

- Core wash and mold paint FURANCLEAN