- Home

- Our Business

- Key technologies

Key technologies

Responding to diverse needs with technology to contribute to the sustainable development of society

Kao meets the diverse needs of a wide range of industries in a wide range of fields with unique technologies that combine key technologies developed through comprehensive research and development activities ranging from the basic material design, reaction control, and precision processing of oils, surfactants, and polymers to their application in respective fields.

Kao's key technologies

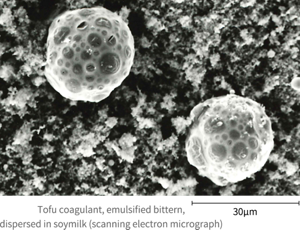

Emulsification

Dispersants are agents used to separate particles that are clumped in a liquid using dispersion forces caused by electrostatic or steric repulsion. For example, cement is an essential particle used to harden and strengthen concrete that forms many of our living environments. However, without the use of a dispersant, the cement particles will clump together, making it difficult to form concrete into the desired shape. Kao has developed a "cement dispersant" that controls the clumping of cement particles, making it dramatically easier to handle when manufacturing concrete. Through the scientific study of particle interfaces, we have developed dispersants for a wide range of fields and applications, including functional materials, electronic materials, and ICT materials, helping to improve the lives of people all over the world.

Dispersion

Dispersants are agents used to separate particles that are clumped in a liquid using dispersion forces caused by electrostatic or steric repulsion. For example, cement is an essential particle used to harden and strengthen concrete that forms many of our living environments. However, without the use of a dispersant, the cement particles will clump together, making it difficult to form concrete into the desired shape. Kao has developed a "cement dispersant" that controls the clumping of cement particles, making it dramatically easier to handle when manufacturing concrete. Through the scientific study of particle interfaces, we have developed dispersants for a wide range of fields and applications, including functional materials, electronic materials, and ICT materials, helping to improve the lives of people all over the world.

Cleaning

Kao views cleaning as an important manufacturing process that can deliver a variety of merits and is developing highly functional water-based detergents harnessing our extensive knowledge in the field of interfacial science, including a range of detergents to replace CFCs and chlorine-based solvents. We are developing a range of detergents using design technology that is also environmentally friendly that can control interfacial phenomena at the nano-level for electronic materials that require extremely precise manufacturing technologies and metal materials that require surface modification. We also offer total solutions, including processes to achieve the quality demanded by our customers at our Precision Cleaning Center.

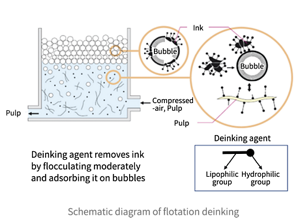

Adsorption and Flocculation

One way to recycle our forest resources is to convert old paper from newspapers and magazines, etc. into pulp, remove the printing ink, and use it as recycled pulp as a raw material for paper. This ink removal process is called "deinking" and a "deinking agent" is used in this process. When deinking is performed using the froth flotation method, it is necessary to separate the ink from the pulp fibers contained in the waste paper, while at the same time, clump the fine ink particles together and cause them to attach or adsorb to air bubbles created by air blown into the pulp suspension. The deinking agent developed using Kao's surfactant technology, optimally controls the interaction between the pulp fiber and ink, the isolated ink microparticles, and the ink and air bubbles, thereby efficiently removing ink to achieve high-quality recycled pulp with a high degree of whiteness.

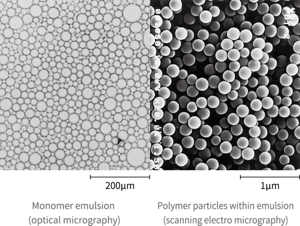

Emulsion polymerization

Emulsion polymerization is a reaction in which a monomer is polymerized in an emulsified and solubilized state by an emulsifier consisting of a surfactant to obtain a polymer emulsion. Emulsifiers are required to perform a range of functions that include the emulsification and solubilization of monomers and the dispersion and stabilization of polymer particles in the resulting emulsions. In addition to the basic functions described above, Kao has developed emulsifiers with a variety of features, that can be used for a wide range of applications, and under a wide range of polymerization conditions, Kao emulsifiers provide emulsions with superior mechanical and chemical stability, excellent water resistance, foam control, and emulsifiers that provide special reactions.

Antistatic finish

The key to preventing a static charge in plastic products is how the antistatic agent kneaded into the resin during the molding process is bled out to the surface to form a thin film. Through detailed research on the compatibility between antistatic agents and resins, Kao has developed a quick-acting antistatic agent that works by bleeding into the surface in approximately one hour after molding. This has made it possible to significantly reduce costs by eliminating the need for aging from molding to delivery. In addition, we have developed antistatic agents for biaxially oriented films, which are effective in low amounts and can be used for food applications, as well as antistatic agents with excellent durability of effect.

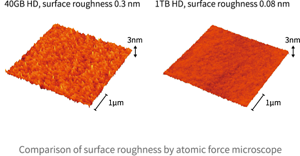

Polishing

The key to increasing the capacity of hard disks (HDD) used in personal computers and video cameras is to smooth the surface of the magnetic disk substrate with high accuracy before the magnetic layer is formed by vapor deposition. Kao has developed a HD substrate polishing agent that achieves both the world's smoothest surface and excellent productivity using a unique method that combines a proprietary nano-sized abrasive grain with chemical treatment of the disk surface. Kao is contributing to an advanced information society by developing technologies that aid in achieving large storage capacity and quality of hard disks.

Polymer designing

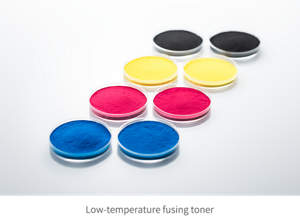

Toner, which is powder ink, is used in printers and multifunction devices. Toner is fine particles of pigment dispersed in a resin called a toner binder, and when heat is applied, the toner binder melts and adheres to paper. More than half of the power consumed by printers is used as thermal energy to melt the toner. To reduce environmental impact, it is important to develop toner binders that can be fused at lower temperatures. Kao was the first in the world to develop a polyester binder that can be fused at low-temperatures by controlling the crystal structure and viscoelasticity. Over the past 40 years, we have been developing toner binders that reduce environmental impact. In recent years, we aim to achieve more environmentally friendly printing through the design of binders using data analysis.

Fragrance

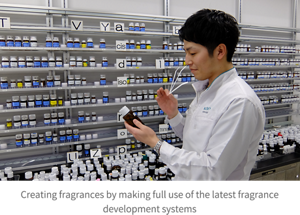

Using results from the latest natural perfume research and synthetic technology, Kao develops a variety of special products that are critical in creating new fragrances. These products, along with joint research from Kao's laboratory in Japan and Spain, have enabled Kao to supply its fragrances to global markets. Kao's principle focus is to develop a unique fragrance that is both versatile and functional.

Pigment nano-dispersion

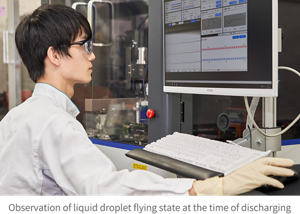

Industrial inkjet printers produce images by ejecting a maximum of 60,000 drops of ink per second from tiny nozzles with a diameter of just 10 microns. In recent years, water-based pigment inks with excellent water resistance and durability have attracted great interest from the viewpoint of environmental harmony. In order to prevent this pigment from coagulating and solidifying in water and clogging the fine discharge nozzles, technology is needed to cover the surface of the pigment with a polymer (encapsulation) and to achieve stable nano-dispersion in water. Kao has developed a highly durable water-based pigment ink for inkjet printers with excellent discharge stability and color development during printing by adsorbing a specially designed polymer on the surface of the pigment and nano-dispersion in water. We have succeeded in realizing water-based inkjet printing even for soft packaging films, which are difficult to achieve with water-based pigments, thereby contributing to a reduction in the environmental impact of packaging containers.

Microstructure control

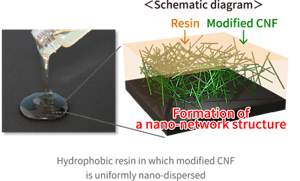

Cellulose nanofibers (CNF, width: 3 nm, length: several hundredths of an nm to several μm) are the ultimate plant-derived sustainable material, and technologies and applications that extract and maximize their potential are in high demand. Kao has developed a unique method of grafting two types of modification groups selected by computational chemistry onto the CNF surface to develop a technology to achieve uniform nano-dispersion of originally hydrophilic CNF into hydrophobic media, such as resins. Through microstructural control, such as the formation of a nano-network and orientation control, it has been revealed that this new CNF exhibits a variety of superior properties. Using this technology, Kao has created increased functional value, such as reduced weight and size, and improved performance in a wide range of materials, and is actively researching this technology in cooperation with internal and external parties to contribute to the realization of a recycling-oriented society.

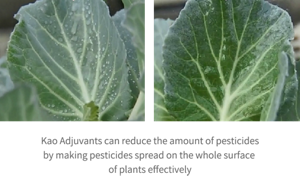

Wetting and permeation

In 2050, the world's population exceeded 9 billion, and food security has become a pressing issue for mankind. Therefore, it is necessary to establish an environment-friendly food production system. Based on the results of essential research, such as the absorption of substances from the leaf surface, internal transfer, absorption from the roots, and a variety of knowledge in the field of interfacial science, Kao is developing a variety of products that contribute to stable and increased food production. One of these is adjuvant products. While selecting environmentally friendly base materials, our adjuvant products improve the effect of agricultural chemicals and also reduce the amount of agricultural chemicals by the enhanced wettability and permeability of agricultural chemicals at the plant interface. Further, we are working on the development of an adjuvant for drone spraying that will meet the needs of smart agriculture, to contribute to increased food production while protecting the global environment.

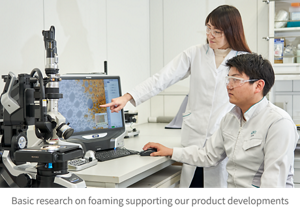

Foam

Foam is found in various aspects of our day-to-day life. The rich foam generated when washing your body, hair, and dishes has provided emotional value in the form of comfort and satisfaction in cleaning products. Kao has researched this foam for many years and has refined its foam design technology to ensure customer satisfaction. In recent years, Kao has discovered a range of functions for sustainable foam that were previously unknown, such as reducing the effect on the skin and improving cleaning power by simply changing the way foam is formed. These technologies have been published worldwide in the form of academic papers and are already being incorporated into ever-evolving cleaning products. Kao's world-leading foam technology is also applied to the development of surfactants that provide rich foam formation in cleaning products, industrial cleaning technology, and foam technology in the civil engineering field.

Reaction control technology

Kao produces raw materials for surfactants, such as fatty alcohol and fatty amine from vegetable fats and oils, and has developed unique catalysts for chemical conversion from vegetable fats and oils. In order to advance the reaction efficiently and selectively with long life in the actual plant, the catalysts structure is controlled in the point of the particle size, supported state of active metal, and the pores that form the flow path of reactant. In addition to the original processes that match these catalysts, we have developed key chemicals manufacturing with high efficiency, low energy consumption, and high quality, thereby practicing good ESG manufacturing.

Kao research & development

Kao is contributing to the sustainable development of society, engaging in research and development day and night to help people all over the world live an affluent life. The Research and Development Division of the Kao Group has two functions: "product development research", which aims to design products and commercialize technologies in response to the needs of consumers/customers, and "fundamental research", which delves deeply into cutting-edge science and technology in various fields to uncover the mechanisms of phenomena in a range of materials. While matrix management that allows both of these fields of research to progress hand-in-hand is helping to create a range of innovative products, collaboration between our Performance Chemicals Research, primarily responsible for product development research, and the Material Science Research, involved in fundamental research, aim to achieve a dynamic and flexible exchange of knowledge in their respective specialized fields and accelerate research and development.

Research and Development

Performance Chemicals Research

The Performance Chemicals Research conducts global research and development activities as a development base for industrial chemical products. The Chemical Research was established in 1991 following a reorganization of our existing research body, and was renamed the Performance Chemicals Research in 2013 after further organizational restructuring. Our domestic development base is based in Wakayama with a branch office in Toyohashi. The Chemicals business is the most globalized segment of the Kao Group, and is responsible for overseeing research bases in four countries in Asia, Europe, and North America. Interfacial science is a fundamental technology for the development of industrial chemical products. Among these, we define "interfacial physical property control technology", "nano-surface modification technology", "functional molecular design technology" and a combination of these as our "core technologies". In addition to further building on these technologies, Kao offers customer-oriented products and solutions to support their success. We are actively developing environmentally friendly products to contribute to a sustainable society in the information and electronics industries, which are expected to grow worldwide.

Material Science Research

In order to create value and contribute to the future of a sustainable society through material science research that is in harmony with nature, the Material Science Research is promoting the design and investigating the principles of action of key materials that form the basis of product value, and the development of highly efficient reaction technology. Interfacial chemistry, polymer chemistry, and catalytic chemistry form our core technologies. The starting point for our research and development in these areas is a deep understanding of the nature of the functions and principles of action that materials produce based on this core technology, and the nature of the reaction process used to synthesize these materials. While playing a role in fundamental research in the field of material development, we also play a direct role in the development of chemical products such as oleochemicals, surfactants, cosmetics, agrochemicals, and synthetic fragrances.

For other technical inquiries, please use the form below.

- Home

- Our Business

- Key technologies