- Home

- Semiconductors & Electronics

- Kao's cleaner CLEANTHROUGH

- Dry film strippers

Dry film strippers

Stripping technology that fully caters to customer requirements

In the manufacturing process of semiconductor packages, package substrates, and printed wiring boards, metal wiring and interconnects are generally fabricated by photolithography. Now more than ever, manufacturing processes using dry film resist (“dry film”) superior in terms of both cost performance and mass production, are being applied.

Following patterning processes that use dry film, it is necessary to strip and remove the dry film, and for many years NaOH (caustic soda) has been used to achieve this. In recent years, amine-based strippers that help to effectively remove dry film have become more widely used, particularly in additive pattern fabrication applications such as SAP/MSAP.

As electronic devices, typified by new technologies, including AI and 5G become more sophisticated, it is becoming increasingly important to improve the performance and reduce the size of semiconductor packages, package substrates, and printed circuit boards, which play a key role in electronic devices. In order to achieve this high performance and size reduction, it is necessary to reduce processing dimensions, and this has resulted in the ongoing development of dry films with higher resolution.

High resolution dry film is generally difficult to remove due to its strong adhesion and crosslinked structure, and there are cases where conventional stripping processes fail to achieve the desired results, increasing the need for dry film stripping agents that can effectively remove the dry film. In the past, dry film was generally used for the fabrication of copper wiring (Cu wiring). However, with the increased use of composite materials in semiconductor packages and multidimensional packages (>2D packages) that have emerged in recent years, it is increasingly applied to the fabrication of copper pillars/posts (Cu pillars/Cu posts) and solder bumps (Sn bumps).

While high-performance strippers are required for such applications, it is also necessary to reduce corrosion and damage to a wide variety of materials and components and this has called for the design of more advanced dry film strippers.

From an environmental perspective also, amine-based stripping agents, which have become the most commonly used dry film stripping agent for high performance applications, contain a large amount of nitrogen, which can lead to an increased load on waste water.

Amine-based strippers are also highly toxic, making it necessary to give sufficient consideration to safety in the work environment. As a result, there is now an increased call for the development of anime-free strippers.

Kao is developing a range of dry film stripping agents based on interface control technology, and will continue to contribute to the information society and environmental preservation.

Circuit pattern fabrication process using dry film

Product information

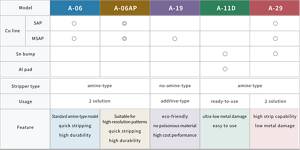

Fast acting dry film stripper

CLEANTHROUGH A-06

CLEANTHROUGH A-06 is a dry film stripper that removes dry film much faster than general NaOH (caustic soda) stripper and other commercially available amine-based strippers. It could help to increase the productivity of each line and reduce the need for investment into new lines.

Dry film stripper for high resolution dry films

CLEANTHROUGH A-06AP

CLEANTHROUGH A-06AP is designed to deliver improved stripping performance, even in cases where the removal of dry film is difficult with general amine-based stripping agents, such as high resolution dry film and high aspect patterning.

Dry film stripper for Sn bump formation

CLEANTHROUGH A-29

CLEANTHROUGH A-29 enables the fabrication of fine Sn bumps by maintaining superior stripping performance while also protecting the tin (Sn) that is often dissolved due to the strong alkaline in general stripper when using dry film for the fabrication of C4 bumps.

Amine-free dry film stripper

CLEANTHROUGH A-19

CLEANTHROUGH A-19 does not contain amines (nitrogen content), a substance that places a significant load on wastewater, or toxic substances, and can help improve stripping performance without increasing environmental load.

Lineup

- Home

- Semiconductors & Electronics

- Kao's cleaner CLEANTHROUGH

- Dry film strippers