- Home

- Semiconductors & Electronics

- Kao's cleaner CLEANTHROUGH

- Cleaning agents for FPDs and precision parts

Cleaning agents for FPDs and precision parts

Eco-friendly precision cleaning agents that aid quality manufacturing

Precision cleaning is an extremely important process in the manufacture of parts to ensure product reliability and post-process quality. In recent years, as the structural design of parts has become more complex in line with the development of ultrafine processing technologies, the need for enhanced levels of cleaning is on the rise, while also becoming more difficult.

However, in the manufacturing process of parts, in general, the importance of precision cleaning has not gained the same level of attention as other manufacturing processes, and there are many cases where optimization studies are insufficient. In saying that, the cleaning process is an important process that has a significant impact on product quality, yield, tact time, and environmental energy costs.

Three types of cleaning agents are widely used in precision cleaning: water-based, semi-water-based, and solvent-based.

Solvent-based cleaning agents (hydrocarbon, chlorides, fluorids, bromides, etc.) have been widely used for many years due to their high oil solubility and quick drying properties. Recently, however, water-based and semi-water-based cleaning agents are becoming a popular replacement for solvent-based cleaners from the viewpoint of work safety and environmental considerations. Water-based and semi- water-based detergents have the advantage of being safer while also having less impact on the environment compared to solvent-based cleaners. The use of surfactants to penetrate, emulsify, disperse, and prevent reattachment enables the simultaneous removal of organic and inorganic contaminants, and demand for water-based and semi water-based cleaners, which both reduce environmental impact and provide superior cleaning performance. These are promising features of water-based and semi-water-based cleaners which is expected to be used for further applications in the future.

From the viewpoint of reducing environmental impact, in addition to the environmentally friendly nature of the cleaning agent itself, it is necessary to contribute to energy conservation and CO2 reduction throughout the entire cleaning process. Most water-based and semi-water-based cleaners require heating to enhance cleaning performance, and in many cases require rinsing with water after cleaning, resulting in high consumption of rinse water waste. By reducing CO2 emissions and energy costs through low-temperature cleaning, and by promoting the reuse and recycling of rinsing water, we are also addressing environmental concerns in the cleaning process.

Kao has accumulated expertise in cleaning a wide range of products, from household items to semiconductors, and by harnessing our proprietary cleaning agent design technology, we are developing a range of precision cleaning agents that demonstrate both excellent environmental and cleaning performance.

Product information

Oil/water separation type precision cleaner

CLEANTHROUGH LC-841

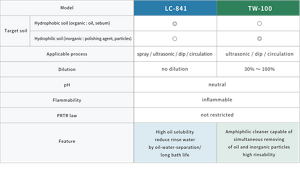

CLEANTHROUGH LC-841 does not contain acids, alkalines, or volatile organic solvents, and with cleaning performance equal to or greater than products that do contain them, helps contribute to improved work safety. Because it is also highly durable, it helps to reduce the frequency with which cleaners are exchanged, helping to reduce waste material. CLEANTHROUGH LC-841 also could utilize oil/water separation, reducing the amount of rinse water required.

Amphiphilic precision cleaning agent for the simultaneous removal of oil/grease and inorganic particles

CLEANTHROUGH TW-100

The unique interface control technology enables the simultaneous removal of oils and inorganic particles with an efficiency equivalent to or higher than that of solvents while being neutral. CLEANTHROUGH TW-100 makes it possible to shorten manufacturing processes by consolidating multiple cleaning processes into one.

Lineup

- Home

- Semiconductors & Electronics

- Kao's cleaner CLEANTHROUGH

- Cleaning agents for FPDs and precision parts