- Home

- Fine ceramics

- KAOCER

Waterborne dispersants for ceramics, KAOCER series

Waterborne dispersants suitable for small particle size filler

Based on the interface control technology Kao has cultivated over many years in a wide range of fields from home use to industrial use, we have developed KAOCER series of applicable to a wide range of dispersoid. KAOCER series provides outstanding dispersion performance for ceramics, metals, silica, carbon black, and other materials throughout the electronic component manufacturing process. This contributes to the enhanced performance and reduced size of electronic devices.

Dispersants for ceramics and metals

KAOCER 2000 series

What is KAOCER 2000 series?

KAOCER 2000 series is the waterborne anionic dispersants. They exhibit high dispersibility for a wide range of ceramics and metal particles. KAOCER 2000 series does not contain metallic ions such as sodium and potassium, and leaves no metal residue after combustion, making it applicable to electronic components.

Feature

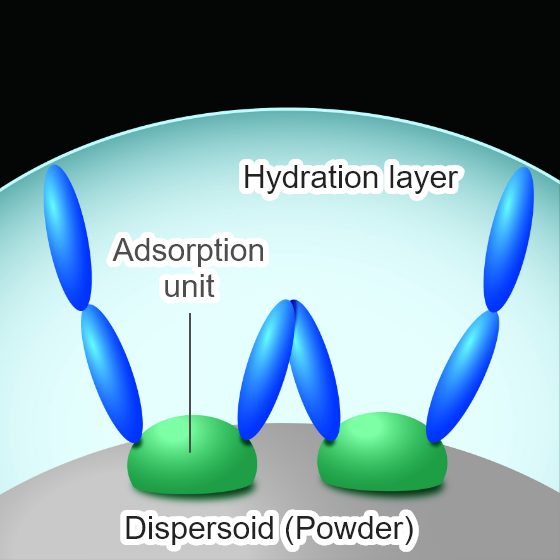

Since KAOCER 2000 series is negatively charged, they exhibit high adsorption performance on positively charged ceramics and metal particles. In addition, the introduction of the insolubilization/adsorption unit in the molecule enhances adsorption to solid particles.

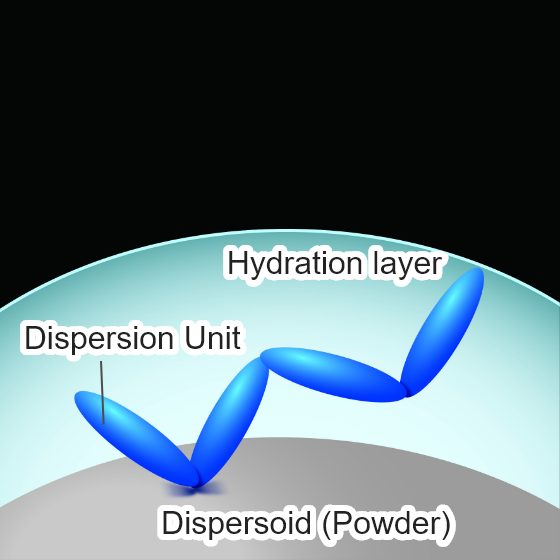

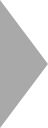

Dispersion mechanism

Since there is no adsorption unit in the molecule, the adsorption rate on the dispersoid (powder) is reduced.

The Insolubilization unit adsorbs strongly to the dispersoid (powder), resulting in the improved adsorption rate to the dispersoid.

The adsorption unit electrically adsorbs the dispersoid (powder), thus increasing the adsorption rate.

Solution

High dispersibility at optimum additive amount

KAOCER 2020

High dispersibility over a wide range of additive amounts

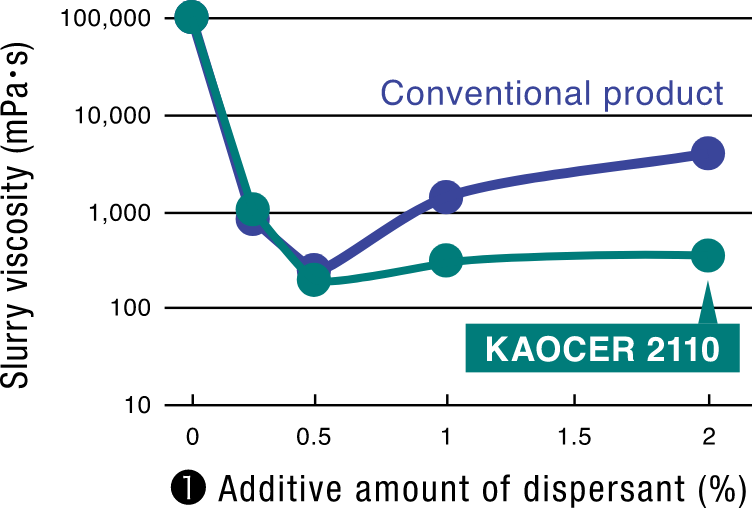

KAOCER 2110

Maintains dispersion for a long period of time

KAOCER 2110

KAOCER 2020

High dispersibility is achieved at optimum additive amount, contributing to smaller particle size of fillers.

Dispersibility of alumina

【Test conditions】

Dispersant: KAOCER 2020 (solid content 40wt%)

Dispersoid: Alumina (average particle size 0.2μm), Slurry concentration 80wt%

Dispersion method: Lab-disperser (2500 rpm x 2 min)

*As solid content

High dispersibility at optimum additive amount

KAOCER 2110

It exhibits high dispersibility over a wide range of additive amounts and little change in viscosity over time,

contributing to long-term slurry stability.

Dispersibility of alumina

【Test conditions】

Dispersant: KAOCER 2110 (solid content 40wt%)

Dispersoid: Alumina (average particle size 0.2μm), Slurry concentration 80wt%

Dispersion method:

① Lab-disperser (2500 rpm x 2 min)

② Static for 30 days after dispersion

*As solid content

*As solid content

Dispersants for silica and carbon black

KAOCER MD-P

What is KAOCER MD-P?

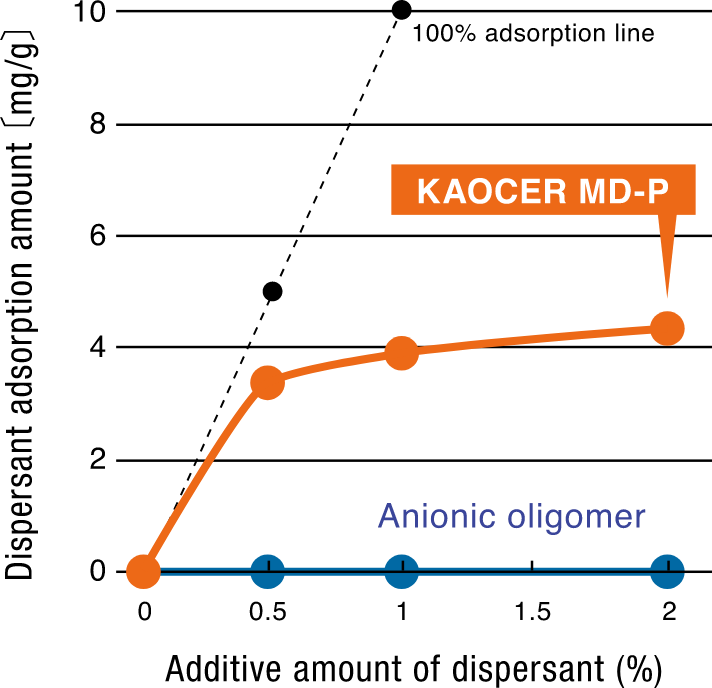

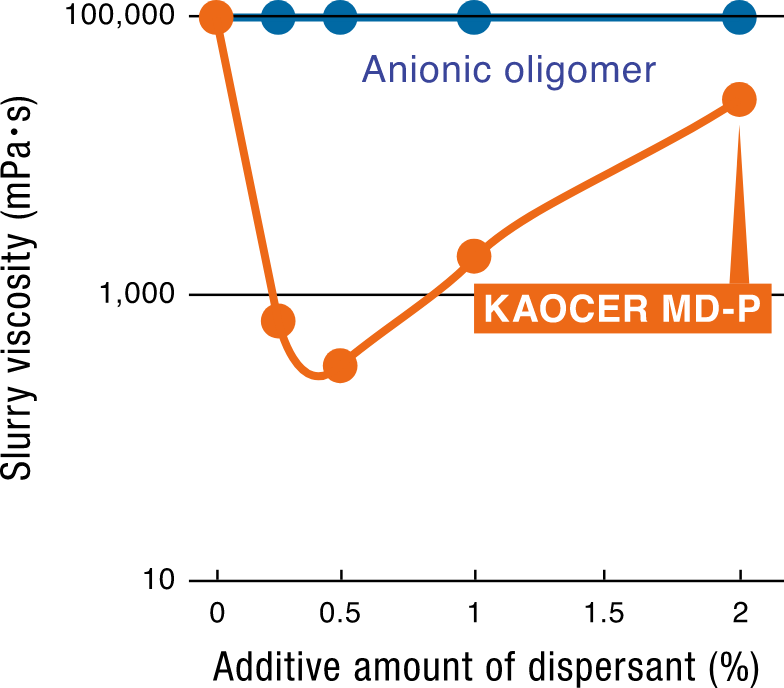

KAOCER MD-P is the waterborne cationic dispersant. It exhibits high dispersibility, especially for silica and carbon black. This product does not contain metallic ions such as sodium and potassium, and leaves no metal residue after combustion, making it applicable to electronic components.

Feature

Since KAOCER MD-P is positively charged, it exhibits high adsorption performance on negatively charged solid particles.

Anionic dispersant

● No adsorption

● No viscosity reduction effect

KAOCER MD-P

● Static repulsion effect

● Demonstrates viscosity reducing effect

Solution

High adsorption performance on anionic solid particles. After adsorption, electrostatic repulsion is utilized to achieve a high dispersion effect.

Dispersibility of silica

【Test conditions】

Dispersant: KAOCER MD-P (solid content 35wt%)

Dispersoid: Silica (average particle size 0.2μm), Slurry concentration 70wt%

Dispersion method: Lab-disperser (2500 rpm x 2 min)

*As solid content

*As solid content

Catalog, SDS, chemSHERPA

| Product name | Product information | SDS | chem SHERPA |

|---|---|---|---|

| KAOCER 2000 | |

|

|

| KAOCER 2020 | |

||

| KAOCER 2110 | |

||

| KAOCER MD-P | |

If you have any questions or require additional information about the dispersants for ceramics for electronic components, please use the form below.

- Home

- Fine ceramics

- KAOCER