- Home

- Plastics & Rubber

- Anti-static agents for plastics ELEC ELESTMASTER

ELEC & ELESTMASTER - Anti-static agents for plastics

Prevents static electricity from building up

Prevents dust and dirt adhering to plastic and causing problems during the molding process

When static charge build up on plastic surface, various problems may occur which not only reduces productivity in the molding line, but also cause dust and unwanted particles to adhere to finished products. Based on the interface control technology Kao has developed over many years, we offer anti-static agents “ELEC" and "ELESTMASTER” for plastics.

We offer various solutions depending on type of resins, molding methods and applications.

Learn more about how anti-static agents work

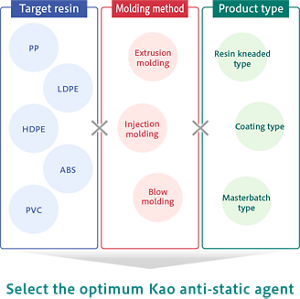

Find from target resins and molding methods

Kao offers three types of anti-static agents; resin kneaded type, master batch type, and coating type.

Antistatic agent we offer for sustainable choices

Find from solutions

Compatible to resin with a high Tg

Anti-static agents kneaded into the resin migrate to the surface of the product, creating an anti-static effect. However, anti-static agents are less likely to migrate to the surface in resins if the Tg (Glass Transition Temperature) is above room temperature or the crystallinity is high. Kao has developed anti-static agents that are effective even in those conditions.

Optimum product

| Target resin | Products | Type |

|---|---|---|

| PS | ELEC PC | Kneaded type |

| ELESTMASTER S-520 | Masterbatch type | |

| ELESTMASTER SB-10 | Masterbatch type | |

| ABS | ELESTMASTER A-1015 | Masterbatch type |

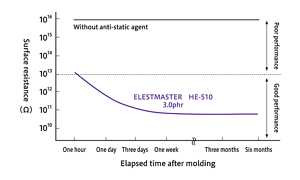

| HD-PE | ELESTMASTER HE-510 | Masterbatch type |

Anti-static effect of masterbatch type HD-PE anti-static agent (Extrusion molding)

Anti-static effect immediately after molding

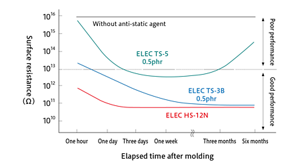

Kao has developed fast-acting anti-static agents which bring high anti-static performance immediately after molding.

Optimum product

| Target resin | Products | Appearance |

|---|---|---|

| PP LLD-PE |

ELEC HS-12N | White needle |

| ELEC HS-12PA | Pale yellow-white solid | |

| PVC (flexible) | KS-555 | Liquid |

Comparison of anti-static agents speed of onset

Preventing volatilization of anti-static agent during molding process

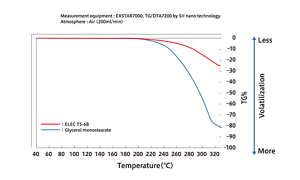

Volatilization of the anti-static agent kneaded into the resin during molding may reduce workability or lead to poor appearance of the finished product. Kao has developed an anti-static agent with excellent thermal stability “ELEC TS-6” with less volatile components derived from anti-static agents.

Optimum product

| Target resin | Products | Appearance |

|---|---|---|

| PP | ELEC TS-6B | Light yellow beads |

Weight change of anti-static agent in thermogravimetric analysis

Contributing to low-carbon society with the use of plant-derived raw materials

Growing environmental awareness is increasing demand for environmentally friendly products.

We offer products using plant-derived raw materials to respond to the needs of different markets and customers.

| Product examples | Features and Applications |

|---|---|

| ELEC TS-5 | *¹ Complies with Food additive White powder |

| ELEC TS-5B-S | *¹ Complies with Food additive White granules |

| ELEC TS-3B | Most commonly used type Good antistatic durability White granules |

| ELEC TS-22B | Low volatility during molding、Excellent heat stability Light yellow granules |

| ELEC HS-12N | Antistatic performance appears immediately after molding White needle |

| ELEC EA | Can be applied to crystalline resin Light yellow liquid (Solidifies during winter) |

| EMASOL L-10V | *¹ Complies with Food additive External type |

| RHEODOL TW-120 | Dissolve in water External type |

*¹ Listed in Designated Additives (Regulations for Enforcement of the Food Sanitation Act Appended Table 1)

Search by application

Kao's anti-static agents can be used in a wide range of general-purpose resin.

Please contact us for more information about our products

As a producer of plastic additives for over a half century, we will support your problems to meet your needs.

- Home

- Plastics & Rubber

- Anti-static agents for plastics ELEC ELESTMASTER