- Home

- Asphalt, Civil Engineering & Construction

- Product lineup

- Water reducing agent for enhanced fluidity under vibration MIGHTY 21V-SG

Water reducing agent for enhanced fluidity under vibration MIGHTY 21V-SG

Concrete that demonstrates both superior flowabilities and resistance to material segregation

Background & challenges

Triggered by noise complaints from neighboring residents due to vibration during the concrete mold filling process

Noise resulting from vibration during the mold filling process at concrete plants can lead to complaints from neighboring residents.Improving productivity is a priority issue in order to make up for the decline in the labor force, and improving the fluidity of concrete offers a solution to this problem.

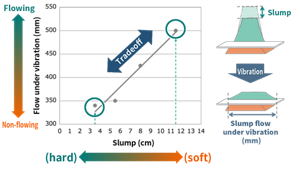

Tradeoff between noise reduction and concrete flowabilities

When added excessively, cement dispersants used to improve the flowabilities of concrete, lead to a defect called material segregation where the aggregate separates from the concrete. As a result, achieving a balance between the flowability of concrete and resistance to material segregation has always been a challenge.In addition, self compacting concrete causes the problem of cost increases and quality control due to the increase in the amount of powder.

MIGHTY 21V‐SG allows concrete to effortlessly flow and fills every corner of the formwork; stopping perfectly when left to settle thereby reducing material separation.

Harnessing its surfactant technology developed in the field of laundry detergents, Kao has succeeded in developing a new, high performance water reducing agent, MIGHTY 21V-SG grants flowabilities for concrete to fill every corner of the mold and Static Stability after filling without material segregation.Our MIGHTY 21 V Series, a high performance water reducing agent based on the concept of achieving both superior flowabilities and resistance to material segregation, as well as good fluidity under vibration, has been well received by a large number of customers.

Features

-

Improved concrete fluidity under vibration, reduced vibration level and vibration time

-

Reduces concrete stickiness, achieving excellent workability

-

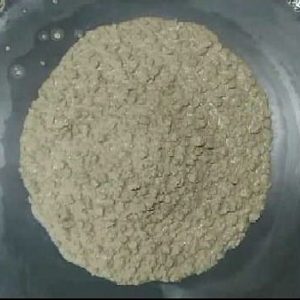

High resistance to segregation makes it possible to reduce the amount of powder

- Reduces stickiness and running when screeding

Main components & physical properties

-

Main components: Polycarboxylic Acid Co-Polymer and special thickener

-

Appearance: Yellow-brown liquid

-

Density: (g/cm3, 20℃) ・・・・ 1.055 - 1.095

-

Does not contain harmful substances that corrode reinforcing steel.

SOLUTION

resistance to segregation

High resistance to segregation makes it possible to reduce the amount of powder

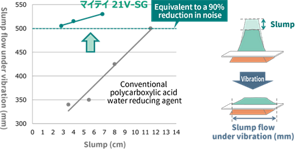

Concrete slump test using a vibrating table(NEXCO Test 733 "vibration deformation test")

[Slump flow before vibration: 500 mm]

[Slump flow after vibration: 700 mm] favorable properties with no material segregation

Fluidity under vibration

90% reduction in noise during vibration casting

- Home

- Asphalt, Civil Engineering & Construction

- Product lineup

- Water reducing agent for enhanced fluidity under vibration MIGHTY 21V-SG