- Home

- Asphalt, Civil Engineering & Construction

- Product lineup

- NEWTLAC 6000SMA, Asphalt modifier made from waste PET for cold regions pavement

NEWTLAC 6000SMA, Asphalt modifier made from waste PET for cold regions pavement

Achieving a balance between the utilization of waste PET and long-life pavement, good workability

Background & challenges

Stone mastic asphalt (SMA) pavement needs better workability and water resistance

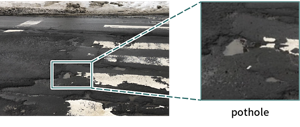

Snowy and cold regions such as Hokkaido area in Japan have problems about ensuring driving safety like road damage (potholes) caused by freeze-thaw of water entered into the pavement and icy road.

SMA pavement has been applied to extend pavements life in snowy and cold regions and to ensure driving safety for vehicles.

SMA pavement is a pavement with a rough road surface to improve drainage and slip resistance to enhance driving safet. In addition, it is a road which reduces ingress of water and improves the durability by filliing a large amount of asphalt binder.

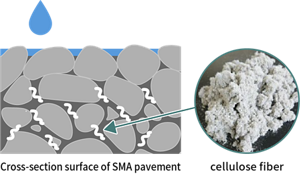

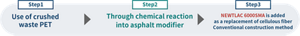

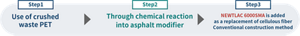

Conventional SMA pavements have improved watertightness of the pavement by using cellulose fibers with asphalt binder, however there is a limit to the amount of asphalt that can be impregnated by cellulose fibers, it was difficult to construct a completely dense pavement body.

NEWTLAC 6000SMA for achieving the utilization of waste PET and better workability

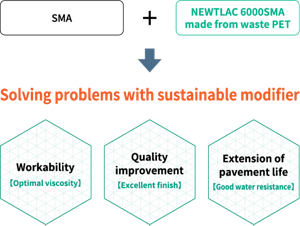

Kao has adopted the waste PET utilizaiont technology of NEWTLAC 5000 to NEWTLAC 6000SMA, and achieved realizaton of a positive recycling technology in cold regions pavement.

NEWTLAC 6000SMA is Kao's unique asphalt modifier that can effectively utilize waste PET, in addition to improvement of workability and realization of long-life pavement life by replacing cellulose fibers.

High adsorption of NEWTLAC 6000SMA

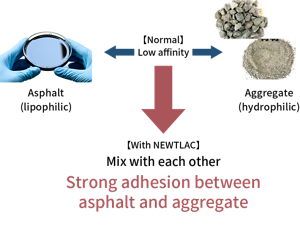

NEWTLAC 6000SMA has the unique property of tightly bonding two materials that are normally incompatible like lipophilic asphalt and hydorophilic aggregate (stone).

This can form a thicker layer of asphalt on the aggregate.

SOLUTION

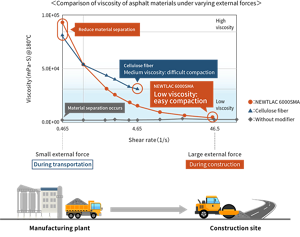

Achieving a balance between stable quality during transportation and good workability during construction

NEWTLAC 6000SMA realizes transporting asphalt mixture that remains in good condition and providing a comfortable construction operation.

<Comparison of viscosity of asphalt materials under varying external forces>

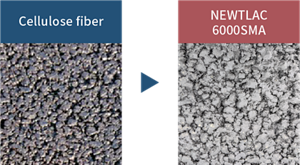

Excellent finish from pavement surface to internal

The better workability improves the quality of the pavement surface and internal conditions.

Surface

Improve more than 10% road surface roughness and increased safety

- Improve drainage from the road surface

-

Improve driving safety by better slip resistance

Internal

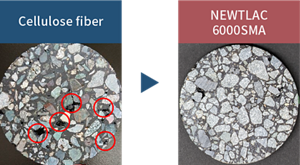

Dense pavement material and longer pavement life

-

Prevention of water intrusion reduces damage caused by freeze-thaw with keeping out water

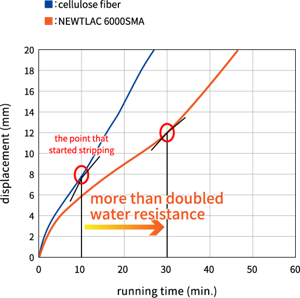

Enhanced water resistance, achieved longer pavement life

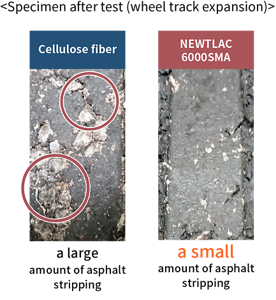

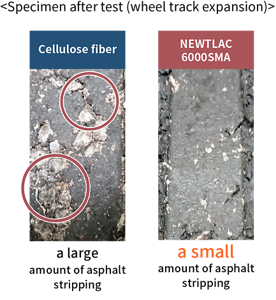

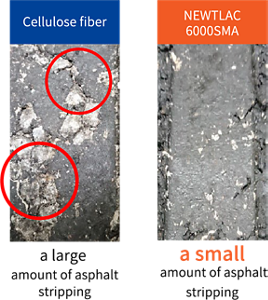

As a result of suppressing asphalt stripping, asphalt durability is improved

because of retaining asphalt coated on aggregate.

<Comparison of water resistance of Asphalt pavement>

Kao original test (Accelerated durability test with repeated running under water immersion conditions)

<Specimen after test (wheel track expansion)>

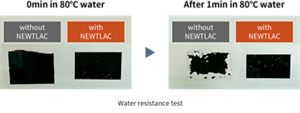

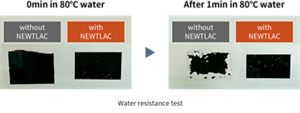

Good water resistance

When glass plates (same composition as aggregate) are coated with asphalt and immersed in warm water, the plate sample with NEWTLAC improved the adhesion of the asphalt by the excellent water resistance.

Water resistance test

- Home

- Asphalt, Civil Engineering & Construction

- Product lineup

- NEWTLAC 6000SMA, Asphalt modifier made from waste PET for cold regions pavement